Maintaining Freshness in Food

DENBA technology is an innovative next-generation freshness preservation technology that keeps seasonal flavor intact by activating water molecules inside food ingredients.

Simply installing a compact device in your existing refrigerator or freezer allows you to experience the freshness-preserving effect of DENBA. Even premium fruits such as grapes and Shine Muscat remain fresh and juicy for up to two months. In meat processing plants that supply supermarkets, drip loss when thawing meat or fish has been reduced by up to 95%. Ordinary freezers can now freeze without damaging cells, and DENBA has already been adopted worldwide in household refrigerators, commercial refrigerators, transport trucks, and containers.

In recent years, the food and food distribution industries have been significantly affected by issues such as climate change due to global warming, disasters like typhoons and heavy rains, and reduced or unpredictable customer traffic due to COVID-19.

In addition, the global movement toward the SDGs (Sustainable Development Goals) is urging companies to take proactive measures.

To all those involved in production, retail, food service, and food distribution, we offer DENBA products that can address challenges such as adjusting shipping times to increase product value, stabilizing prices by suppressing oversupply in the market, expanding sales channels, extending freshness periods to maintain prices, and reducing food waste.

Difference from other products

① High safety

Many conventional freshness preservation technologies apply high voltage directly to food. While this method can offer certain effects, it also presents significant risks due to the high voltage.

Such methods can leave food electrically charged, and there have been reports of electric shock when handling food with wet hands during cooking.

DENBA, on the other hand, uses a low-voltage solution that applies an Extremely Low Frequency (ELF) electromagnetic field and is certified by PSE, making it a highly safe product.

② Affordable cost and high versatility

Freshness preservation devices generally fall into two categories: integrated systems and add-on types.

Integrated systems are built into refrigerators or freezers and often require completely new equipment. In restaurants with limited kitchen space, this can be a major issue.

DENBA is an add-on system that can be installed in your existing refrigerator or freezer.

This greatly reduces the initial investment cost, starting at around one-fifth to one-eighth the cost of an integrated model.

It is also compatible with walk-in refrigerators, large cooling units, trucks, and containers, making it highly adaptable across different industries and scales.

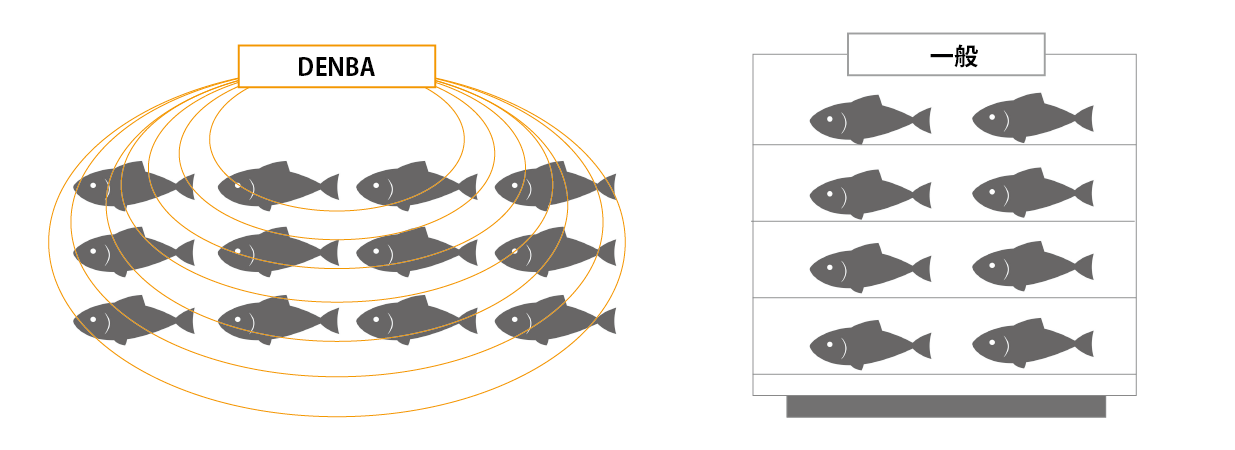

Unlike similar products, DENBA works across the entire space.

③ Lower Monthly Operating Cost

DENBA, developed as a new standard for freshness preservation, offers numerous technical advantages. Among these, the most highly rated by customers is its remarkably low operating cost.

Traditional high-voltage preservation devices require a significant amount of electricity, which inevitably results in high monthly electricity bills.

DENBA takes a completely different approach. By using its unique technology that maintains freshness through resonance of water molecules, it minimizes power consumption.

Because it operates at only 10 volts of low voltage, in Japan the monthly electricity cost is just 20 yen (approximately 145 yen to 1 US dollar), showing a dramatic difference compared to conventional high-voltage solutions.

④ Saving space

Compared to conventional refrigeration, freezing, and thawing equipment, it does not require a large amount of space.

Comparison Summary

| Other companies' products | DENBA |

| ・Many competing products use high voltage ranging from 3000V to 10000V, directly applied to food for freshness preservation, freezing, and thawing. ・Similar electric field devices require stainless steel plates to be installed throughout the interior of the refrigerator, resulting in high costs for additional installation. Relocation also incurs significant expenses. ・Due to the high voltage, electricity costs are also substantial, creating a heavy financial burden. | ・Freshness preservation, freezing, and thawing are achieved by applying low voltage and low frequency to the food. ・A static electromagnetic field is formed throughout the storage space, making it adaptable to various locations. It can be removed and reused during relocation. ・Compared to other products, it requires less installation space, helping reduce initial and operational costs. ・Because it operates with low voltage, monthly operating costs are significantly lower than those of other products, improving overall profitability. |

\ Contact us now /