Achieving high-quality freezing without stressing the ingredients

Food does not freeze down to minus 4°C, but once freezing begins, it freezes faster than in conventional methods.

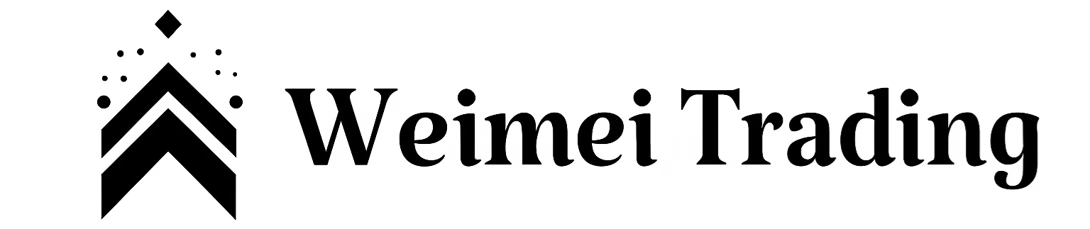

By using DENBA for freezing, food can be frozen while maintaining freshness without damaging the cells.

In other words, even without using ultra-low-temperature freezers at minus 50 to minus 60°C, high-freshness freezing is now possible with standard freezers operating at minus 18 to 25°C.

Point 1: Comparable results to rapid freezing even with a standard freezer

Effect

There is a temperature range called the maximum ice crystal formation zone, between minus 1°C and minus 5°C, which food passes through during the freezing process. As the name suggests, this is the range where water molecules inside food most actively turn into ice.

During the freezing process, the range from minus 1°C to minus 5°C is where water molecules are most likely to become ice, and it is known as the maximum ice crystal formation zone.

When water turns into ice, its volume expands by approximately 1.1 times, which easily causes cell membranes to rupture.

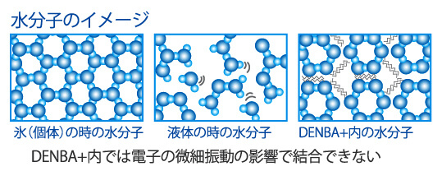

In rapid freezing, this temperature zone is passed through quickly to prevent the formation of large ice crystals and minimize cellular damage. On the other hand, DENBA technology activates water molecules through resonance and keeps them from freezing down to minus 4°C. By preventing the formation of ice, it enables high-quality freezing with minimal stress on the food.

What is the maximum ice crystal formation zone

When freezing food, the temperature drops rapidly until it reaches the freezing point below 0°C. However, between minus 1°C and minus 5°C, the temperature decreases very slowly. This is because most of the cooling energy is used to remove latent heat of fusion, which is about 80 kilocalories per kilogram of water. This temperature range is called the maximum ice crystal formation zone.

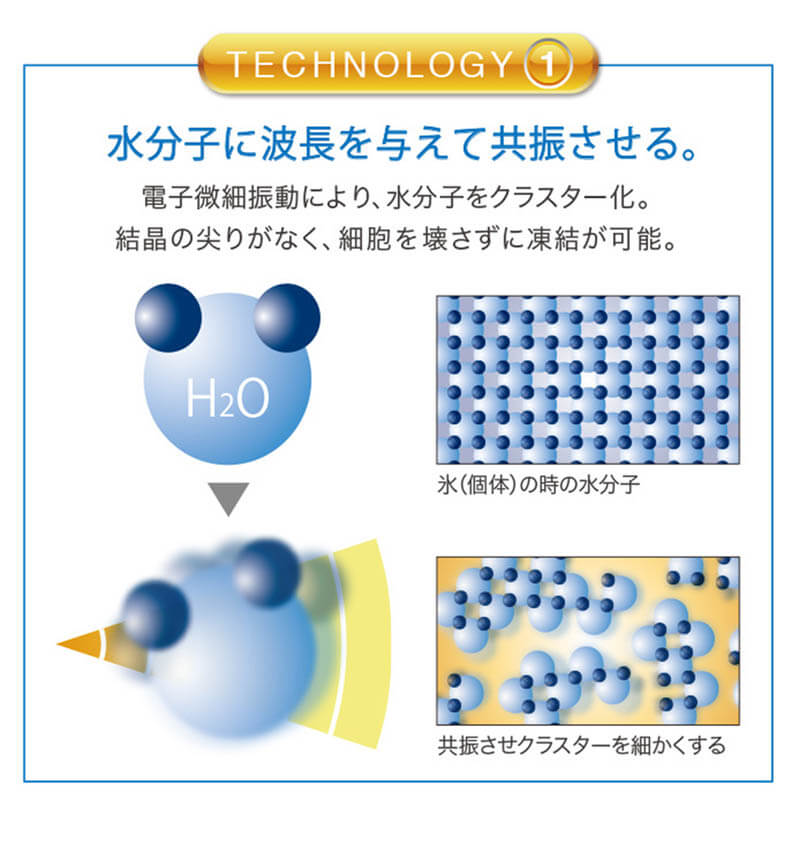

Point 2: Technology that allows freezing without damaging cells

In conventional freezing, the ice crystals that form tend to have sharp edges, which break the cell walls inside the food and cause drip when thawed. In contrast, freezing with DENBA technology applies vibrations at the same wavelength as water molecules, causing molecular resonance. This breaks down clusters into smaller units and results in spherical ice crystals, allowing freezing without damaging the cellular structure of the food.

Point 3: Also effective for energy saving and CO₂ reduction

Compared to ultra-low temperature rapid freezing equipment at minus 60°C, DENBA offers energy-saving benefits and reduces carbon dioxide emissions.

Example in restaurants

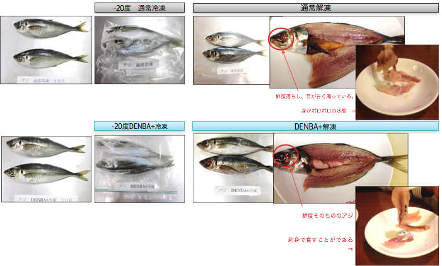

Normally, blue-backed fish are prone to rapid bacterial growth, so slow freezing under typical conditions results in quality deterioration, making it impossible to serve thawed horse mackerel as sashimi.

However, with DENBA, for the first time in the world, horse mackerel frozen using conventional slow freezing at temperatures between minus 18°C and minus 25°C retained remarkable freshness even after thawing, making it suitable for serving as sashimi.

Restaurant owners have praised the technology, saying, "The moment I put the knife in, I could tell how fresh the horse mackerel was. It's unbelievable that such freshness can be achieved with slow freezing and thawing."

DENBA+ラインナップ

既存設備へ「後付け」できることで買い替えに比べて大幅にコストを圧縮できます。

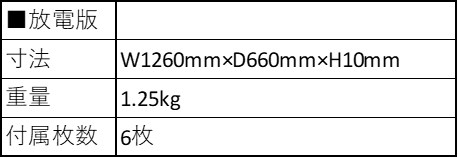

DENBA+2.0

プレハブ型冷蔵・冷凍庫向け

DENBA+3.0

プレハブ型冷蔵・冷凍庫向け

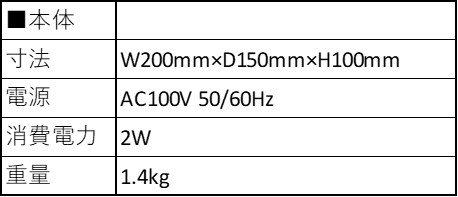

DENBA Fresh Pro

業務用冷蔵・冷凍向け

\ 今すぐお問い合わせください /